PU SANDWICH PANEL

MULTI-CHOICES

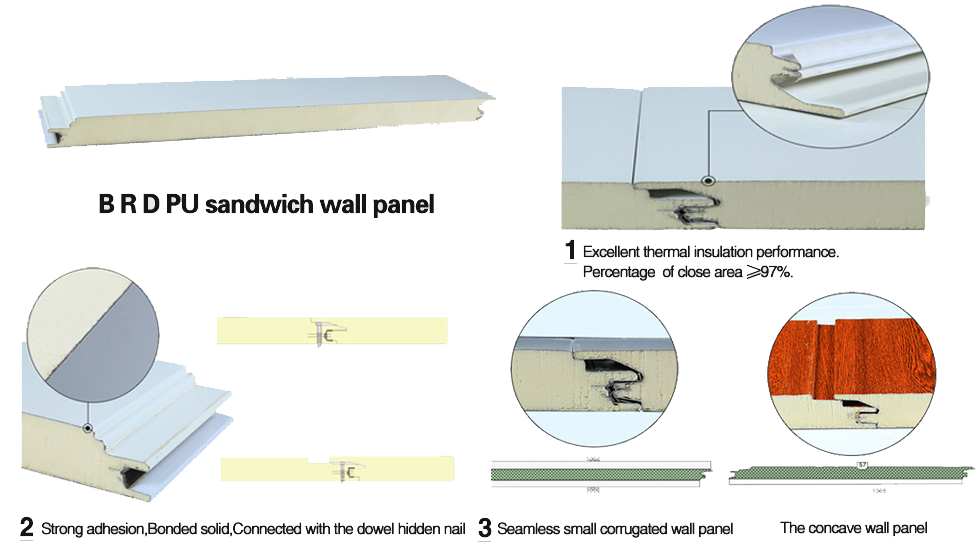

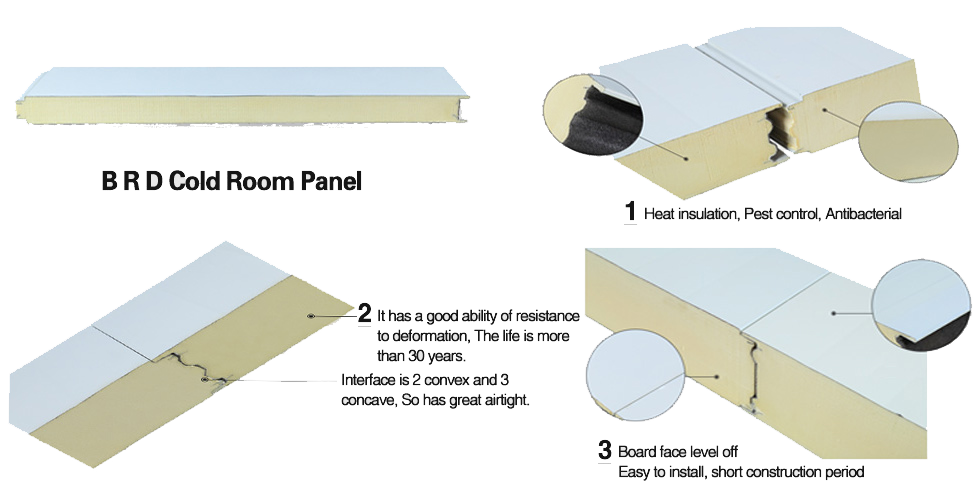

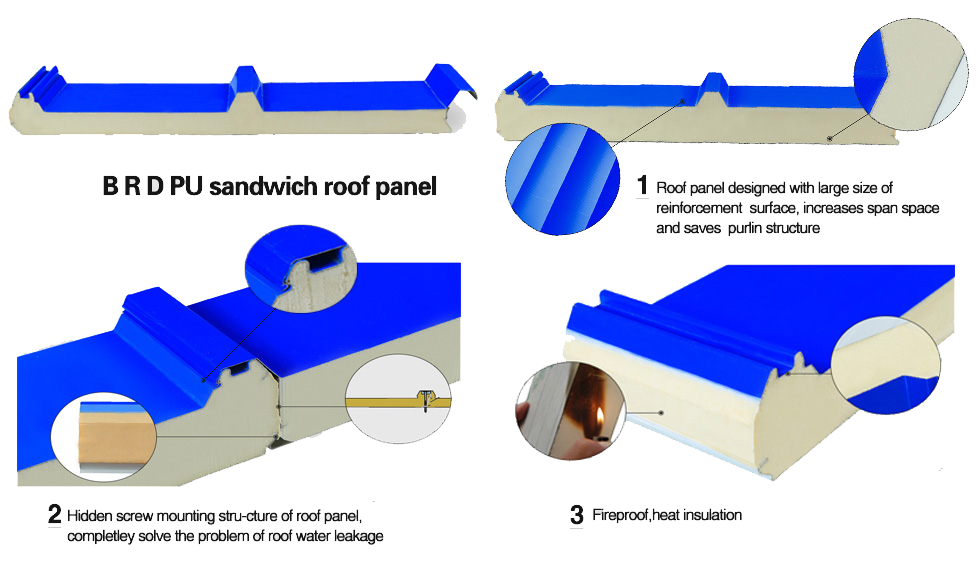

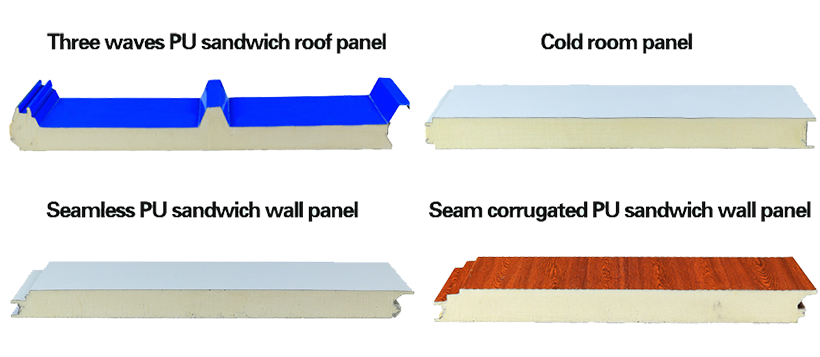

According to different usage of insulated panels, PU Sandwich Panel can be divided into three types: Wall panel, Roof panel, Cold Store Sandwich Panel. Widely used in industrial and commercial buildings, Cold Storages, Clean Rooms,warehouses and prefab buildings.

SUPER INSULATION

Low thermal conductivity of pu sandwich panels with excellent thermal insulation properties, can greatly reduce the thickness of periphery of the building structure, which effectively increasing the interior area of the building and save energy and costs.

Advantage

Super flame retardation

Economical

Durable

Ecological

Easy and quick installation

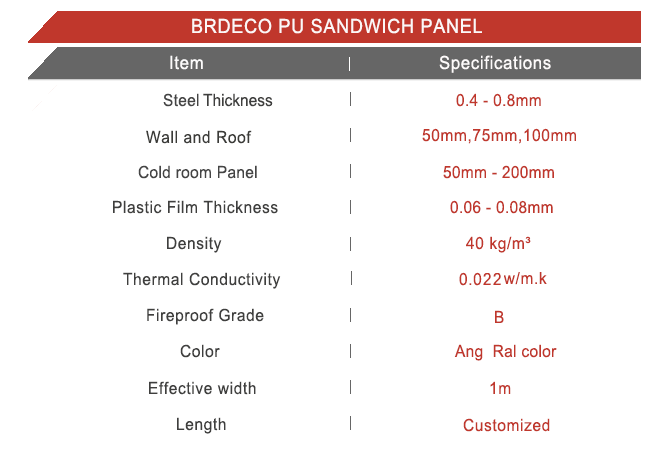

Technical parameters

Cold room panels with different thickness are applied for different temperature requirements.

| Temperature range | Thickness of cold room panel |

| 0 ℃ - - 5 ℃ | 75mm thick |

| -10 ℃ - -18 ℃ | 100mm thick |

| -25 ℃ - -36 ℃ | 150mm thick |

| -36 ℃ lower | 200mm thick |

Manufacturing technology

The classification of PU sandwich panel by raw material. There are four kinds that PU sandwich panel, rock wool sandwich panel, glass wool panel, EPS panel.

The type of roll coating. There are three kinds that galvanized steel sheet, stainless steel, aluminum magnesium manganese plate. The normal thickness of galvanized steel sheet is 0.4-0.7mm, the stainless steel is 0.3-0.4mm, the third is 0.5-0.7mm, they all come from Tianjin or Shandong.

Installation

FAQ

What is PU Sandwich panel (Polyurethane sandwiched panel)?

Worry about the quality and delivery time of PU Sandwich Panel?

Why the temperature of cold room can’t satisfy you?

Do you have cold room door?

How to deal with the gap between the cold storage plate and the plate?

How much is your cold storage board density? Socket is?