ROCK WOOL PANEL

100% NON-COMBUSTIBLE

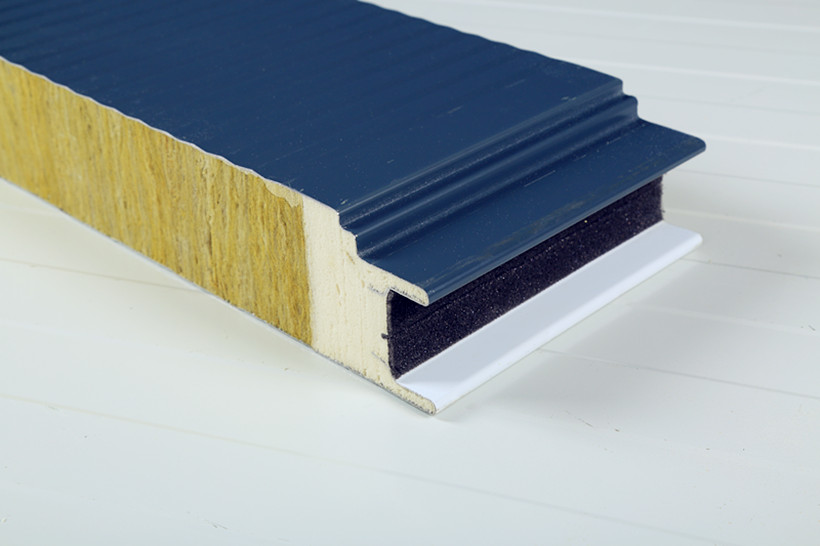

Rock Wool Sandwich Panels are consist of two outer metal sheets (steel or aluminum) with high density basalt as core insulation. Due to the excellent performance thermal fire and acoustic insulation, stone wool core sandwiched panels are commonly adopted for fire-resistance and acoustic applications.

SUPER SOUND ABSORPTION

Rock Wool Sandwich Panels are the most effective acoustic insulators used in construction.Take the 50 mm thick rock wool sandwich panel for example and the panel can absorb the sound over 30 db/m2.Widely used in the steel structure factory building, activities room, roof, wall, air clean room ceiling and partition.

Advantage

COST SAVING & DURABILITY

FIRE SAFETY

SOUND INSULATION

FAST CONSTRUCTION

LONG LIFE TIME

Technical parameters

| Name | Specification |

| Density of rockwool | 120-140kg/m³ |

| Effective width | 1000mm |

| Thickness | 50mm, 75mm, 100mm |

| Length | According to customer's request, normal less 11.8m |

| Color | Blue, red, white gray,as customized |

| Surface Material | Galvanized ,stainless steel, aluminum steel |

| Steel Thickness | Nomal: 0.4-0.7mm |

Manufacturing technology

Rock wool sandwich panel used the assembly line production process, give full play to the rock wool core material of the unique properties, such as fireproof, sound-absorbing, and good use polyurethane excellent waterproof performance, and avoids the shortcoming of rock wool bibulous absorb moisture, let polyurethane, rock wool board got fully the advantages of integration, to carrier to save, thus effectively extend the service life of the product.

1) seal, not bibulous. Effectively prolong the service life of the product.

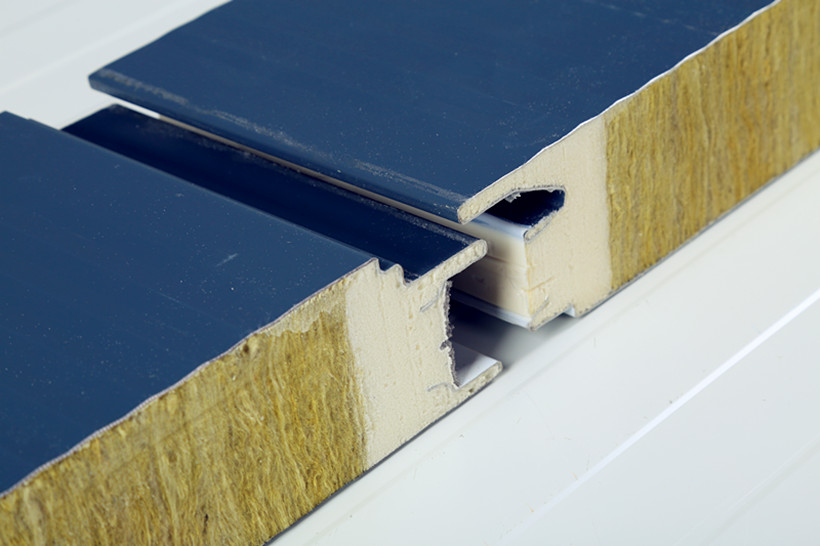

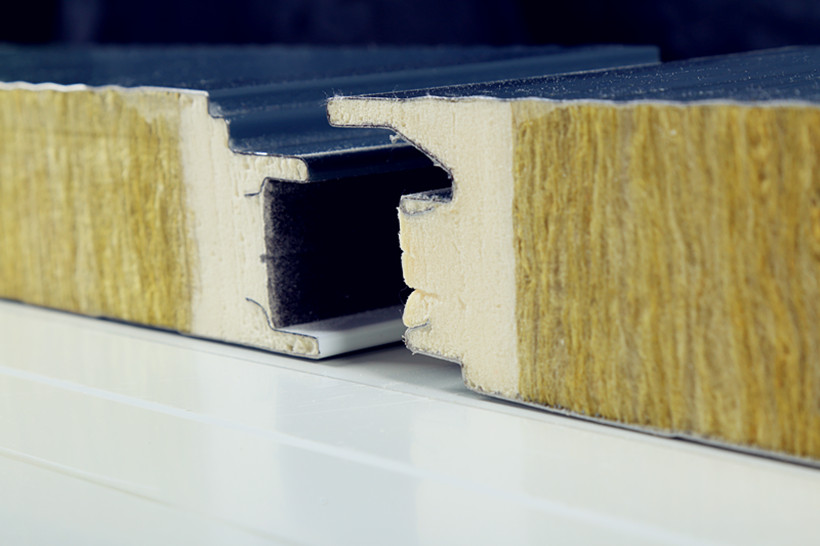

2) beautiful performance: the interface design with European standards, and smooth, round shape, board face level off beautiful, seams, reliable strength, effectively prevent the formation of hot and cold bridge.

3) strength good: polyurethane sealing rock wool on both sides with two layers of steel plate and core material bonding into a whole, to work together, plus the roof plate surface wave pressure type, its overall stiffness is far better than the pressed powder rock wool, glass wool cotton) the site of the composite plate. Sandwich board by fitting and purlin fixed, greatly improving the overall stiffness of roof, roof to strengthen the overall work performance.

4) reasonable hooking way: rock wool board connected by hidden-interlocking roof polyurethane sealing side, to avoid the roof plate joint leakage hidden trouble, save the dosage of accessories.

5) fixed firmly reasonable methods: polyurethane seal rock wool roof plate self-tapping screws on both sides set up between the two plate seam roof plate wave location, and the use of special waterproof structure, avoid to produce waterproof vulnerabilities.

6) short installation period, polyurethane sealing side rock wool sandwich panel, due to the site without secondary processing, the average daily installation area of 600 ~ 600 square.

7) anti scratch protection: rock wool sandwich board in the production of polyurethane sealing side, can paste polyethylene adhesive protective film on the surface. To avoid the transportation and installation process of the steel plate surface coating from scratch or wear.

Installation

1. You need to ensure that the heat preservation facilities and pipeline surface drying, there is no leakage. rock wool board and rock wool felt have to butt joint closely in order to let the heat loss minimum,

2. It is best to use metal or plastic package on its surface when the rock wool products for outdoor insulation or where vulnerable to mechanical wear, and pay attention to the joint tightness and sealing. If used in cold areas, it must be combined with a layer of moisture proof layer on the surface.

3. The polyurethane rock wool insulation board must be combined with appropriate outer sheath when the temperature is greater than 200 degrees Celsius, and it won't make the product thickness and density of change.

4. It must be combined with the heat preservation nail, and to guard against when used in large diameter or wall rock wool insulation products equipment and the temperature is greater than 200 ℃.

FAQ

Why choose Our rock wool sandwich panel?

Rock wool sandwich panel, what brand?

What is core material of rock wool sandwich panel?

what is the appl[gation of rock wool sandwich panel?

Are your products made mechanically or manually?