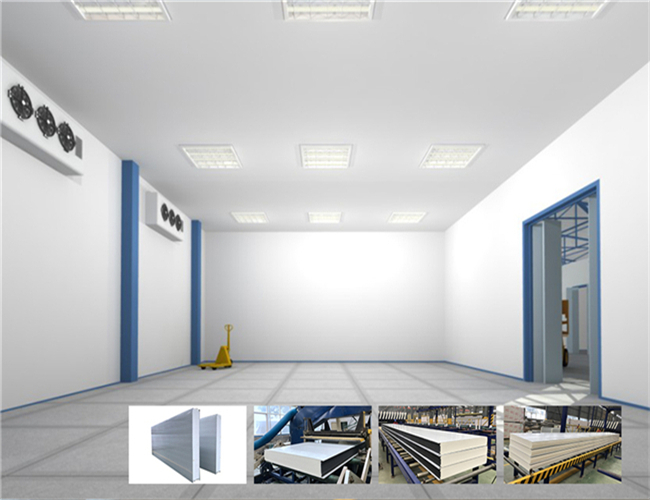

COLD ROOM PANELS

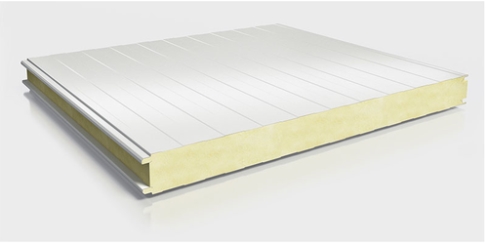

PU Cold Room Panel used the high density polyurethane foam, the best qulity steel sheet as surface. Great temperature-resistance make It has no deformation from -110° C to 120 ° C.

Advantage

Super flame retardation

Economical

Durable

Ecological

Easy and quick installation

Technical parameters

|

Component |

Top Steel Sheet |

Core Material |

Bottom Steel Sheet |

|

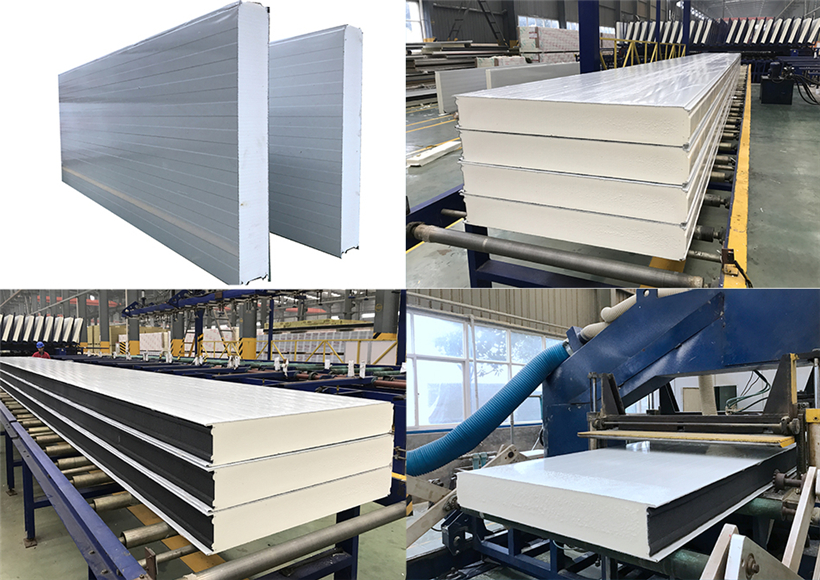

Thickness |

0.4-0.7mm (normal use) |

50mm,75mm,100m,125mm,150mm,200mm (Standard Choice) |

0.4-0.7mm(normal use) |

|

Material |

PPGI,PPGL,Stainless Steel |

Polyurethane |

PPGI,PPGL,Stainless Steel |

|

Type Mode |

1000mm |

||

|

Length |

As Building Design |

||

|

Color |

White, white-grey, or any RAL color |

||

|

Steel Strip |

Galvanized plate 0.4mm-0.7mm thick |

||

|

Application |

Various walls and ceilings, partitions, referring to the cooler room, cold storages,clean room, Pharmaceutical Workshop etc. |

||

|

Advantages |

High R-value, thermnal insulation |

||

|

Fire Retardant |

|||

|

Good durability |

|||

|

Competitive price |

|||

|

30 years service life |

|||

|

Fast-installation |

|||

The different thickness Cold Room Panels are applied for different temperature requirements.

| Temperature range | Thickness of cold room panel |

| 0 ℃ - - 5 ℃ | 75mm thick |

| -10 ℃ - -18 ℃ | 100mm thick |

| -25 ℃ - -36 ℃ | 150mm thick |

| -36 ℃ lower | 200mm thick |

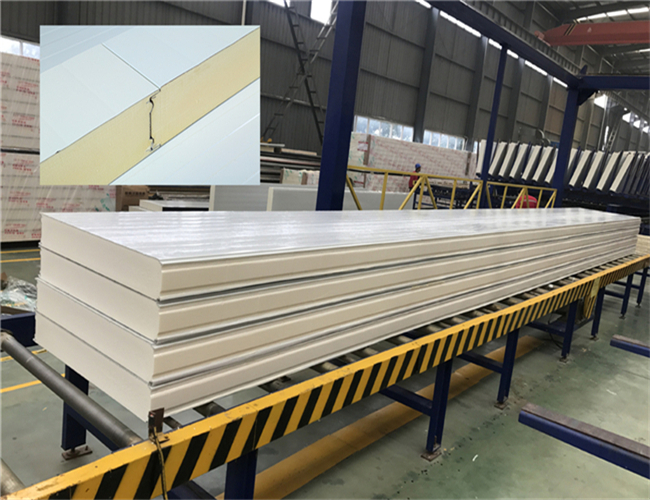

Manufacturing technology

1. High load intensity, low water absorption, long service life, outstanding thermal insulation and great stability in low and high temperature.

2. Lightweight, non-toxic, odorless and eco-friendly; Good supporting, heat resistance and sound insulation.

3. It can cement with steel plates, cements, fiberboards, bricks and many kinds of materials and normally would not fall off with great thermal insulation and waterproof properties.

4. The unique foaming craft enables the panel to have low thermal conductivity and good size stability. The panel is suitable for construction in low or high pressure.

5.High thermal stability: No obvious change of volume and intensity when the temperature is lower than 120° C;

Low thermal conductivity: 63J (m. H. K) (15cal/m. H. K) when the density is 0.03kg/m3.

6. The installation is convenient and flexible with no need of large-scale lifting devices to shorten the construction period and lower the cost.

Installation

1, First of all, it must carry on the construction preparation before installation, include personnel, materials, etc. All will be well prepared.

FAQ

What is PU Sandwich panel?

What is the annul output

What is the Minimum order quantity?

How many days of shipping to my country?

How can I get a price?

Make Orders

CONTACT US

Contact us using form bellow